Let’s Talk About Plasticiser

The polymer sector plays host to a range of on going discussions regarding plasticiser. It brings about the question of how and why some thermoplastic materials can be modified for greater toughness and deformability.

What is plasticiser?

In discussions about plasticiser, the most basic distinction made is between internal and external plasticisation.

In the case of internal plasticisation, a second component is integrated into the base polymer by means of copolymerisation. This effects an increase in the mobility of the molecular chains and a change in the chemical binding force between the polymer chains.

External plasticisation can essentially be defined as the production and physical mixing together of polymer mixtures. However, unlike with polymer blends, this process involves the use of low-molecular substances or oligomers. The smaller the plasticising molecules, the better the desired result. The short-chain nature of the molecules means higher vapour pressure, which in turn leads to higher volatility and an increase in emissions.

How is plasticised PVC made/produced?

Plasticised PVC (polyvinylchloride) is obtained via external plasticisation. This means that a plasticising substance such as diethylhexyl phtalate (DEHP) is incorporated into the polymer to increase the distance between polymer molecules and, in turn, the mobility of the molecular chains. DEHP, like dioctyl phtalate (DOP), is classified within the EU as teratogenic and harmful to fertility and is banned from use in specific applications, including in children’s toys.

How does plasticisation work with other thermoplastics?

For polymers such as polyamide (PA), plasticisation occurs with varying degrees of water intake. The water content of PA is dependent – among other factors – on the amount of moisture in the surrounding environment. Should PA be allowed to dry out and placed in an anhydrous atmosphere, embrittlement will occur.

In practice, these fluctuations have scarcely any impact, since a swelling of the polymer is only observed after a certain amount of time has elapsed. Nevertheless, the addition of glass fibres or beads is sometimes used to counteract the absorption of water. They minimise the water content and slow down the absorption process.

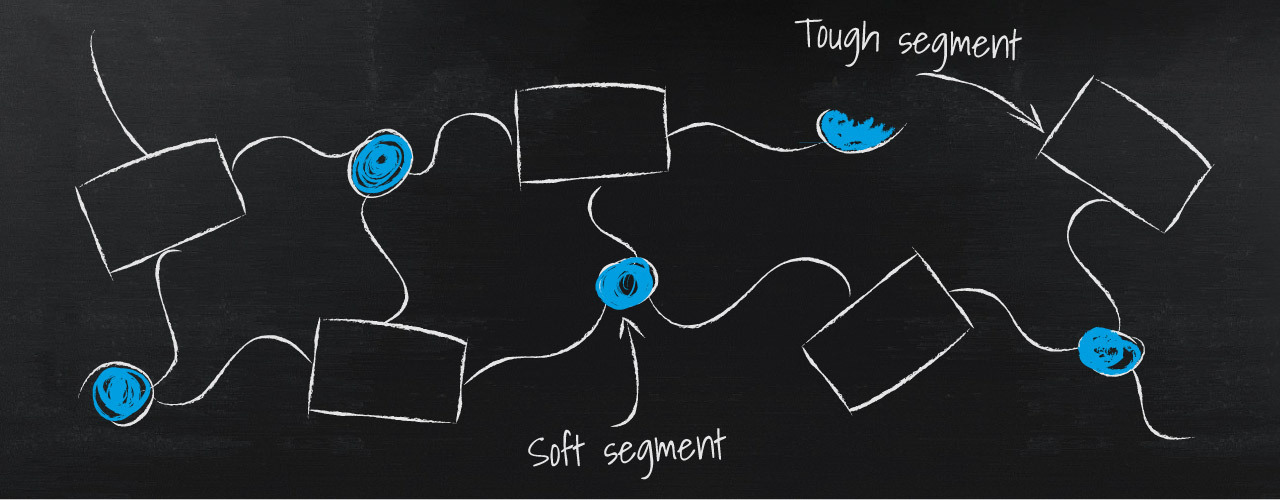

For linear polyurethane (PUR), also known as thermoplastic polyurethane (TPU), the macromolecules exist in blocks (block copolymers). These are multiphase polymers containing a disperse physical cross-linked main phase and a coherent soft phase. In contrast, PUR rigid foams consist only of an amorphous polymer structure.

What role do the properties play?

The use of different polymer blends and the addition of additives enable the properties of polymers to be adjusted as desired, eliminating the need to rely on low-molecular – and therefore volatile – plasticisers.

Need a modification?

We optimise the stiffness-toughness relationships of polymers according to your requirements and adhere to all currently applicable ECHA guidance. Contact us for more information!