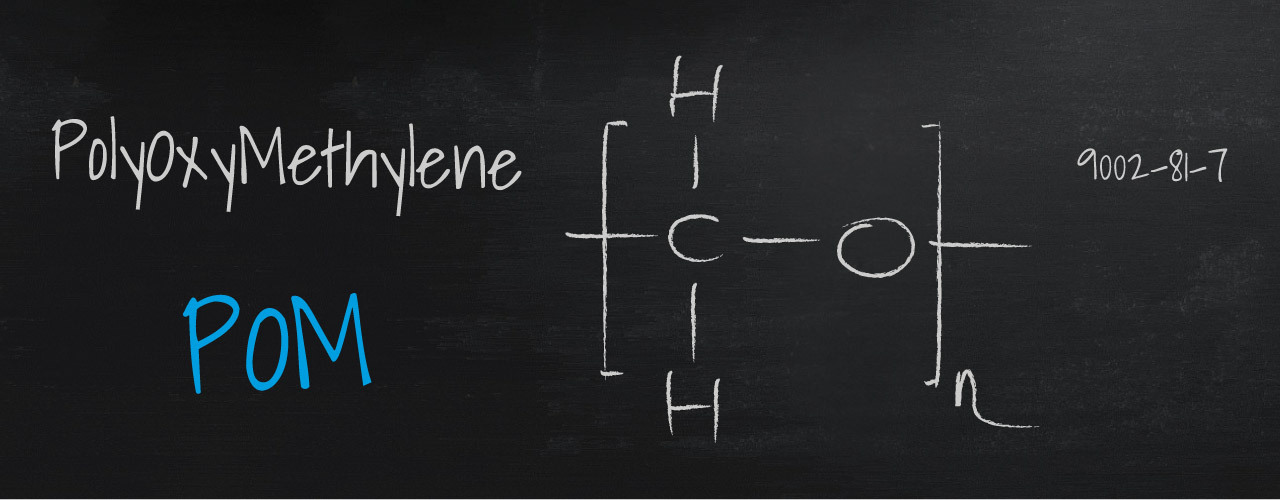

Polyoxymethylene – POM

The range of base materials we use is offered in a variety of custom-tailored modifications, carried out according to the chemical structure of the compounds in question and to our process-related expertise. POM is one of the thermoplastics polymers we produce, and its unique and very particular range of properties is useful in fulfilling a number of technical requirements. For us, an important part of the process consists in putting forward a few different materials and briefly summing up of the basic properties of each.

What is POM?

Polyacetal (polyoxymethylene) is a high-molecular, semi-crystalline thermoplastic polymer.

How is POM produced?

A distinction is made between homopolymers (POM-H) and copolymers (POM-C). The former is produced through cationic polymerisation of trioxane or direct polymerisation of formaldehyde. The latter is formed from copolymerisation of trioxane and dioxane.

What makes POM favourable to use?

High levels of stiffness and strength at a wide range of temperatures are two of the characteristic material properties of POM. Others include:

– High dimensional stability at high temperatures

– Low water absorption

– High toughness at low temperatures

– High abrasion resistance and low coefficient of friction

– Good electric and dielectric properties

How can POM be processed?

POM is used predominantly in injection moulding and extrusion moulding processes. It is suitable for all currently established welding procedures, including HF welding. Following the necessary surface pretreatment, it is also suitable for bonding processes.

What are the applications for which PA is particularly well suited?

POM’s excellent properties render it usable in a wide variety of technical applications. These include:

– bike wheels, sliding elements, housing components,

– snap-on and press fitting connections, spring elements, chains, castors, pump parts,

– plug connections, bobbins, isolators,

– joint housing, switches,

– fittings, handles and hinges.

Need a special modification?

We supply polyamide within made-to-measure product solutions. Contact us for more information!