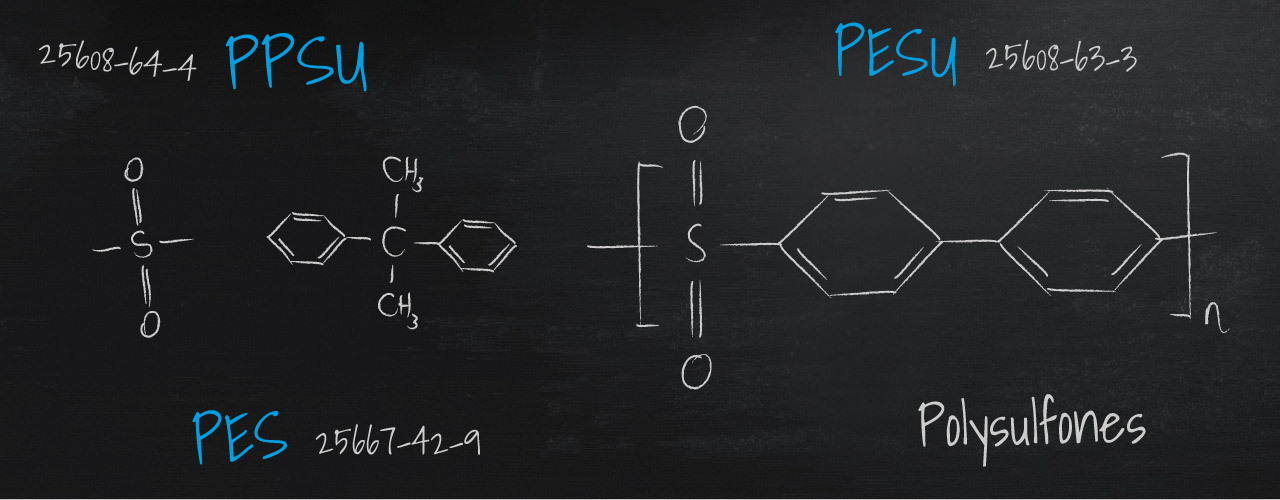

Polysulfones – PSU, PESU, PPSU

In situations where plastics like polyamide (PA), polycarbonate (PC), polyacetale (POM) or polyterephtalate (PET, PBT) fail to satisfy the necessary technical requirements, high performance plastics like thermoplastic polysulfone come into play. Within the polysulfone category, we differentiate between polysulfone (PSU), polyethersulfone (PESU) and polyphenylsulfone (PPSU). These materials provide options within the field of heat-resistant plastics. With certain special modifications, they can be made suitable for use in high-quality technological parts.

What are polysulfones (PSU, PESU, PPSU)?

Members of the polysulfone family are among the most amorphous thermoplastic materials available. Due to their chemical structure, they are used primarily in high-temperature applications.

How are polysulfones produced?

PSU is produced via a multi-stage polycondensation reaction with bisphenol A and dichlorosulfonyl sulfone, which results in a linear amorphous structure. PESU is created through polysulfonation or polyester synthesis. In the case of PPSU, special, complex processes are necessary for achieving the requisite high-level properties and low water absorption characteristics.

What are PSU, PESU and PPSU used for?

All members of the polysulfone family exhibit excellent stability at high temperatures. However, they have certain other differentiating characteristics:

PSU is predominantly used in applications requiring high creep resistance and suitability for high continuous service temperatures alongside the usual requirements of high mechanical stability and stiffness. A light amber amorphous structure, it enables transmission of light and has high dimensional stability and good hydrolysis resistance.

Like PSU, PESU is an amorphous transparent plastic with a light yellowish colour. Its properties are similar to those of PSU, although PESU exhibits a higher impact strength and better chemical resistance. Its stiffness and stability are high and its notch sensitivity is low.

PPSU has better impact strength than PSU and PESU. It also has higher chemical resistance – particularly to cleaning and disinfecting agents – and a very low rate of water absorption, which makes it suitable or applications involving superheated steam sterilization. Other properties of note are its good dimensional stability and excellent resistance to high-energy radiation.

How can polysulfone be processed?

As with other thermoplastic materials, polysulfone can be processed using injection moulding and extrusion methods. Due to the fast rate of water absorption, care should be taken that the moisture content is below 0.02%.

For which applications is polysulfone particularly well suited?

Polysulfone is generally used in highly-stressed structural components. Its applications include:

– computer parts, insulation, electrical switch parts, capacitor film;

– casing for electronic equipment, terminal strips;

– pump casings, impellers, covers, coil bodies;

– handles, sockets, instruments requiring hot air and steam sterilization;

– membranes, hollow parts, machine parts;

– and rolls, valves or fittings.

Need a special modification?

Polymerwerkstatt supplies polysulfone within made-to-measure product solutions. Contact us for more Information!